LEXINGTON, Ky. — Supply chain problems created by the COVID-19 pandemic have had an unintended benefit: job creation.

What You Need To Know

- The COVID-19 pandemic created supply chain problems

- More than 250,000 jobs have been created in the United States since the beginning of 2021

- More than 3,200 jobs have been created in Kentucky

- Thirty-two companies have added jobs in the Commonwealth

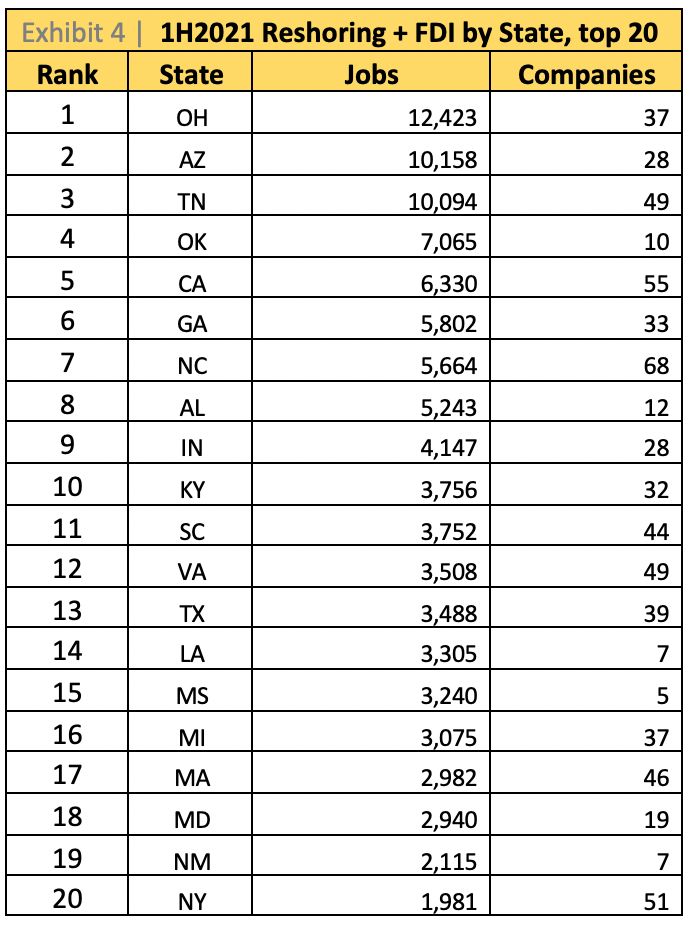

Many domestic manufacturers and American workers, subsequently, have benefitted from the unreliability of foreign suppliers by bringing their operations back from abroad. The trend is known as “reshoring” and it is estimated to have brought around 250,000 jobs back to the United States in 2021. While Ohio, Arizona and Tennessee saw the highest job growth because of the reshoring initiative, Kentucky ranked No. 10 with 32 companies adding nearly 4,000 jobs in 2021, according to the Poynter Institute.

According to the Reshoring Initiative, which was founded in early 2010 to help manufacturers realize local production, and reduce the cost of ownership of purchased parts and tooling, over 138,000 jobs were projected to return to the U.S. in the past year while 1,334 companies were expected to reshore. In addition, foreign direct investment (FDI) job announcements would total to over 220,000–38% above 2020 and the highest annual number ever recorded.

GE Appliances announced this past October plans to invest $450 million and add more than 1,000 new jobs by the end of 2023 at its Appliance Park headquarters and manufacturing operation in Louisville.

“GE Appliances continues to bring manufacturing back to the United States — creating jobs and economic growth,” said Kevin Nolan, president and chief executive officer for GE Appliances. “We want zero distance between us and the millions of families across America we serve with our products.”

According to the Wall Street Journal, shipping rates to the U.S. east coast have increased by $9,000 on average since January 2020 and manufacturing products in the United States changes arrival time from six to eight weeks to about a week.

“As GE Appliances grows, Kentucky and our residents stand to benefit,” Kentucky Gov. Andy Beshear said. “This substantial investment will better position the company for the years ahead and will create quality job opportunities for Kentuckians.”

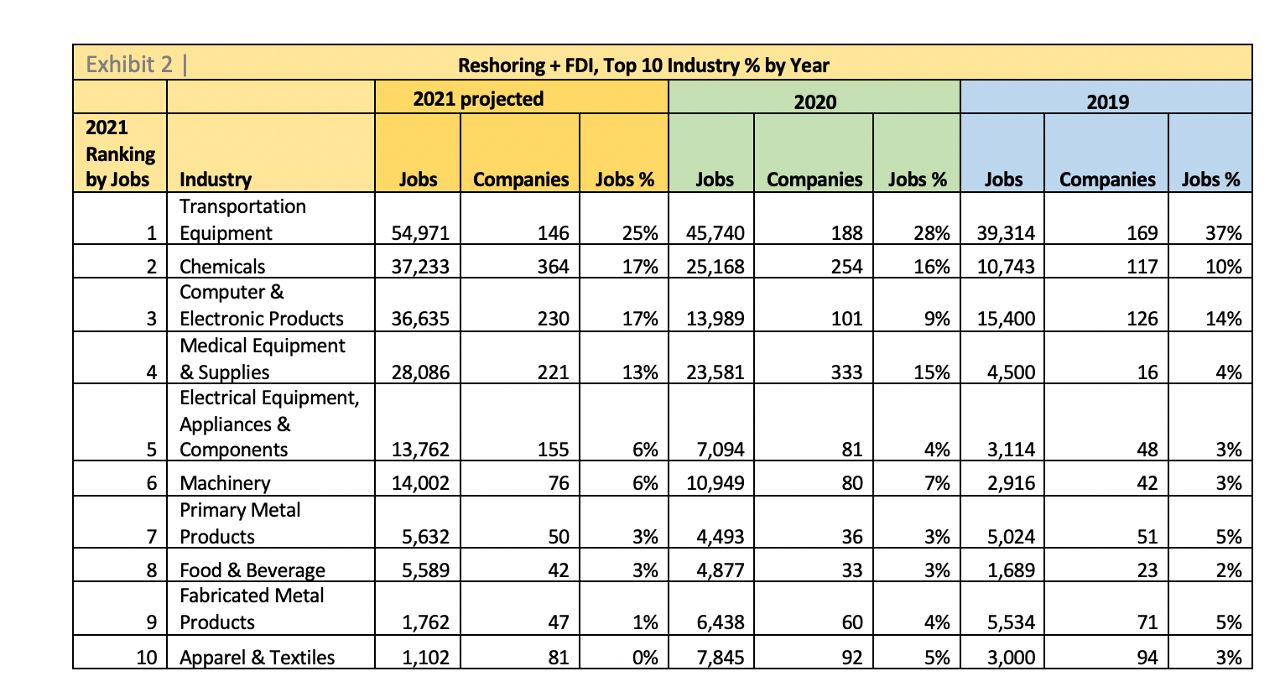

The projection of jobs for the essential products the Biden administration has focused on — chips, EV batteries, PPE, pharmaceuticals and rare earths — represents 28% of job growth (62,500 jobs). According to the Reshoring Initiative website, it is believed some essential products would have come back without the Biden push, as essential products represented 33% of 2020 jobs.

Ford Motor Company and its battery partner, SK Innovation of South Korea, announced plans this past October to build twin battery plants in Glendale, Kentucky, to help power the automaker’s next generation of electric vehicles.

For the second year in a row, reshoring job announcements outpaced FDI — 62% to 38% — and the number of companies reporting new reshoring and FDI also set a new annual record at more than 1,800 companies.

“We believe that the rate of jobs coming from China is largely under reported in our data,” according to the website. “This is because much of the new essential product production is what we define as ‘automatic reshoring’ — where domestic production is replacing imports where a high percentage of the product has traditionally been imported. In many of these cases, the work is displaced from China, but factory announcements do not report the country whose imports are replaced.”

More than 7,300 of GE’s 15,000 employees work in Kentucky. Appliance Park is home to five plants that produce washers, dryers, dishwashers and refrigerators, and parts and components.

“When you think about our product lines, the things that we’re offering, we’re also having to invest in equipment in assembly lines,” said Cinthy Fanning, GE Appliances vice president of dishwashers. “We’re adding line shifts and those mean all new jobs to support the new products.”

Tyson Foods is also moving forward with plans for a $355 million manufacturing operation in Bowling Green, creating 450 full-time jobs in one of the largest new investments in Bowling Green’s history.

The company will build a 400,000-square-foot manufacturing facility in the Kentucky Transpark for production of Jimmy Dean and Wright Brand bacon. Company leaders expect construction will be complete in late 2023.