LEXINGTON, Ky. – Ask business owners what their goal is and many will say, “To make the world a better place.” Few of those business owners, however, can say they have actually done so, but that is not the case for Twyman Clements, co-founder and CEO of Space Tango in Lexington.

What You Need To Know

- Space Tango provides low-Earth orbit research in a variety of sciences

- Company has partnered with NASA and SpaceX

- Lexington business sends CubeLabs to International Space Station

- Site has been visited by NASA administrator

Not many people have heard of Space Tango, which is lodged inside an unassuming brick building on Winchester Road. Even fewer people are aware of what it does.

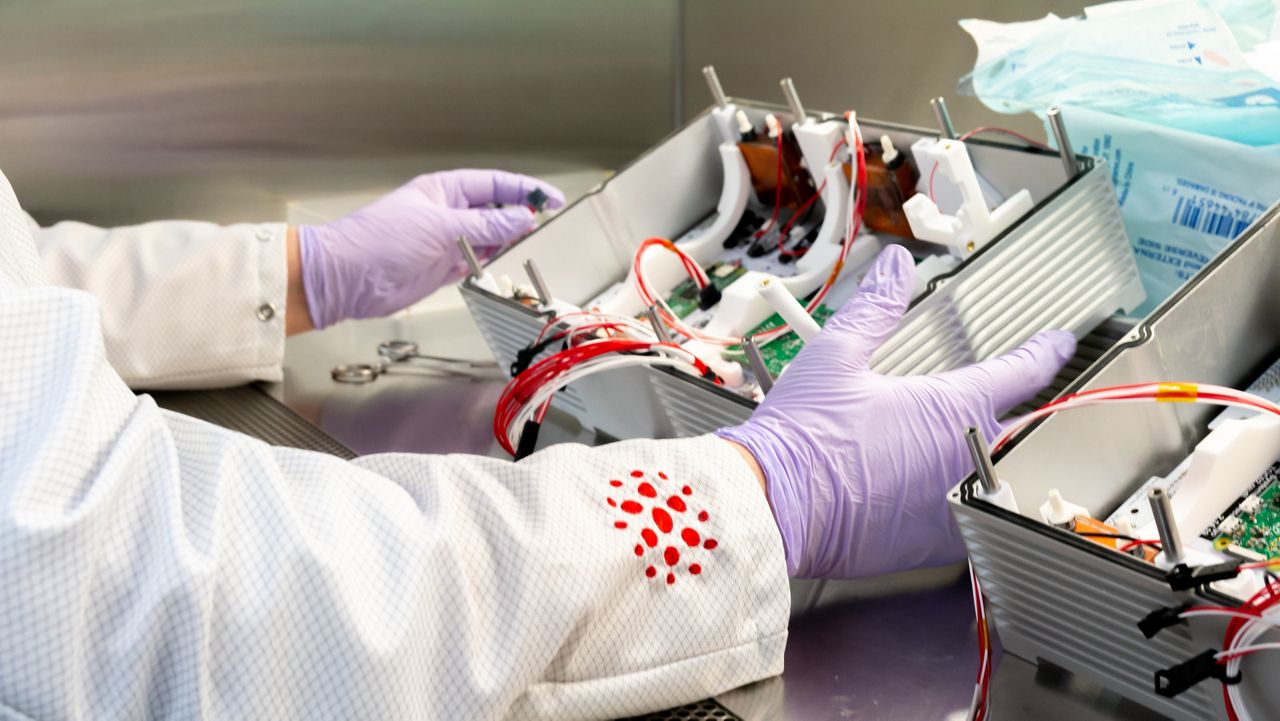

The company provides access to microgravity for research and development and manufacturing on the International Space Station U.S. National Laboratory through automated platforms that can support a variety of sciences. By simplifying and standardizing many aspects of experiment design and integration, Space Tango’s goal is to make the research and manufacturing in microgravity efficient, affordable and scalable.

“Coupled with our expertise in technology and scientific consulting, we guide partners through the process of designing, integrating and operating their investigations in space – a multiple-step process – affording them the opportunity to focus on the science,” Clements said. “Space Tango continues to support our diverse partnership programs and projects in cell-culturing, tissue chips, thin-film manufacturing, flow chemistry, plant science and microbiology. Leveraging this experience, Space Tango is developing new commercial market sectors in space with ST-42 — a fully autonomous orbital platform designed specifically for scalable manufacturing in space.”

Space Tango grew out of a partnership that began in the labs of Kentucky Space. Then graduate-student Clements and Kris Kimel, the CEO of the Kentucky Science and Technology Corporation (KSTC) at the time, set out to simplify and increase access to space-based research and product development.

Founded in 2014 by Clements and Kimel as a commercial spinoff of Kentucky Space, Space Tango manufactures health and technology products in space that have the potential to create cross-industry paradigm shifts on Earth.

Space Tango’s first operational TangoLab facility was installed on the International Space Station U.S. National Laboratory in 2016. A second facility was installed in 2017. Space Tango has designed and flown a variety of research and development projects using automated CubeLabs. Since 2017, the NASA Space Act Agreement has enabled Space Tango to continue providing facilities on the International Space Station to support iterative research and development and manufacturing.

“Space Tango’s mission is to manufacture health and technology products in space that create value and transformational solutions,” Clements said. “As a leader in automated systems, Space Tango pursues pathways to on-orbit production. Our vision is to inspire, innovate and create a better future for humanity by utilizing the environment of space.”

The company Clements and Kimel originally co-founded was called e-10 Space.

“I was named CEO, and I hated that name,” Clements said. “So, I asked if we could change it, and they said I could, but I basically had until the next day to come up with something. At the time, one of the affiliated organizations within KSTC was running a business accelerator called Space Tango. So I thought, 'Well, I'll just take that name.' The reason that business accelerator was called Space Tango was because starting a business is a combination of different things – it's very much like a dance – so that's where the name came from and is a result of my lack of creativity.”

There is a live feed from the International Space Station in what is called the control room at Space Tango, and Clements checks it routinely. The CubeLabs belonging to Space Tango are checked for power and temperature of the air for cooling, among other things.

“This stream is provided to us by NASA,” Clements said. “If something needs changing, we can control everything from a computer. Almost everything's automated so we can reset it. If we need the crew to do it, we can request it.”

The Space Tango CubeLabs currently on the International Space Station contain experiments related to carbon nanotubes and stem cells, among others.

“When you remove gravity, it creates this unique environment that creates better products and things you could never make on Earth,” Clements said. “When you're doing something like a layer deposition process, you need a still homogenous fluid so you can get the bonding right for whatever protein metallic substance you're using to create the layering. The way you get a still image in this fluid is you remove gravity so that you don't have thick sediment due to the different densities.”

Aside from NASA, Space Tango’s projects have also created a partnership with SpaceX. The team is currently preparing CubeLabs for the SpaceX CRS-22 launch this coming June.

Space Tango partner payloads made their departure for the International Space Station from the NASA Wallops Flight Facility this past February for Northrop Grumman’s 15th Commercial Resupply Services mission (NG-15).

The team at Space Tango has formed a partnership with LambdaVision and principal investigator Dr. Nicole Wagner to demonstrate the feasibility of manufacturing a pilot-scale protein-polymer-based layer-by-layer deposition process to develop artificial retinas in low-Earth orbit (LEO). During this flight, the LambdaVision-Space Tango partnership is collecting data to optimize processes for science, automated hardware, and a regulatory process that will establish a baseline for future biomedical applications for in-space manufacturing.

“LambdaVision and Space Tango’s goal is to leverage microgravity to improve upon layer-by-layer deposition to produce the first protein-based artificial retina to restore meaningful vision for patients who are blind, or have lost significant sight due to advanced retinal degenerative diseases, including retinitis pigmentosa (RP) and age-related macular degeneration (AMD),” Clements said.

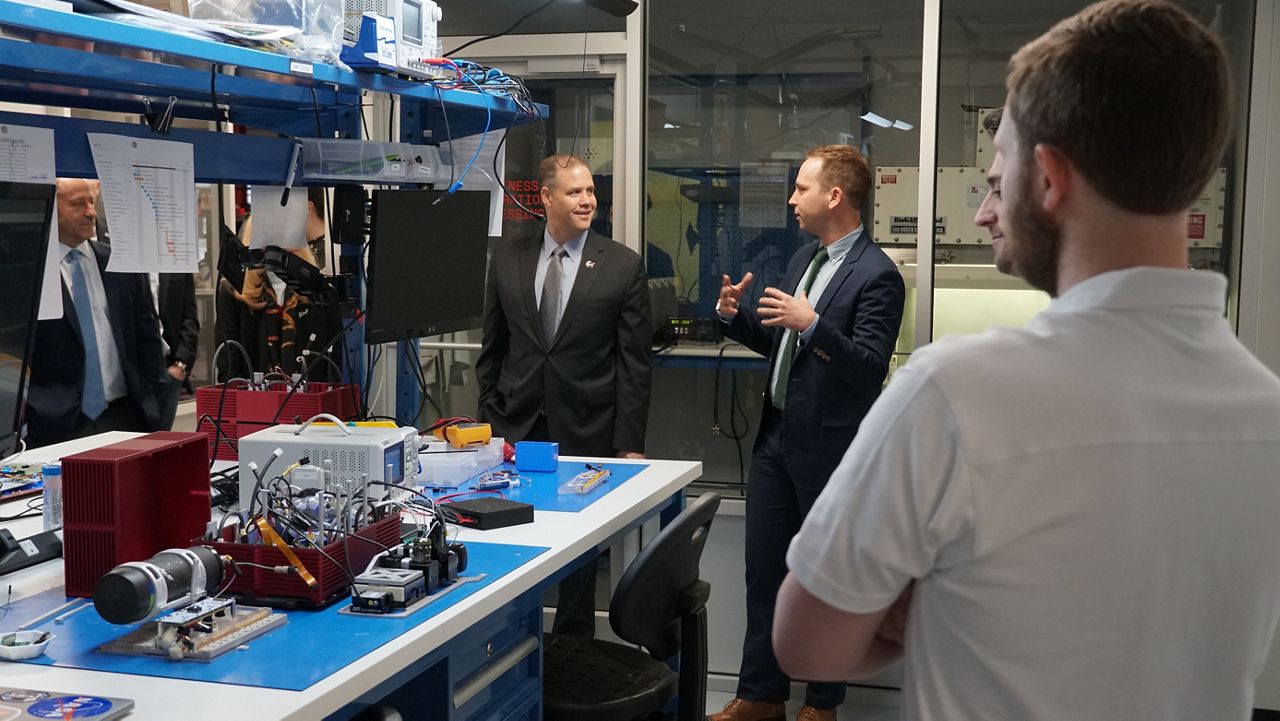

Space Tango’s work prompted an in-person visit from NASA Administrator Jim Bridenstine in May of 2020 where he presented Clements several awards for LEO Commercialization of Biomedical Applications.

Clements leads a multidisciplinary team to deliver automated products that operate in the microgravity environment of LEO. He is frequently recognized for Space Tango’s innovative contributions to developing a new market infrastructure in LEO. He was inducted into the Kentucky Entrepreneur Hall of Fame and is a 2018 recipient of Fast Company’s 100 Most Creative People in Business.

Under his leadership, Space Tango is maturing these research and hardware capabilities for sustainable manufacturing in space where microgravity is an asset to both the production process and their partners. Space Tango continues to excel in providing efficient and cost-effective product development cycles and rapid delivery of configurable systems to Fortune 500 companies, startups, research foundations and academic institutions.

Before Space Tango, Clements, 34, served as a senior space system engineer at Kentucky Space where he developed high altitude balloons, CubeSats and other International Space Station hardware. Clements received a bachelor’s and master’s degree from the University of Kentucky in mechanical engineering where he first began developing the original product architecture for Space Tango.

“I grew up just outside of Bardstown on a farm and we had cattle and tobacco and several other things,” Clements said. “While an undergraduate, I started working in a lab that was building two balloons, and then satellites and I did some work on the International Space Station. That's what kind of got my feet wet in this industry.”

While working on improving payload development for the space station, Clements said it became obvious how beneficial zero-gravity is for science and manufacturing.

“That's where the ambition of the company grew over several years,” he said. “I had many jobs up until graduate school, but this is the only job I've done since. It's very enjoyable.”

Space Tango has satellite offices in Texas and Florida, but Clements is proud to have started the company and kept its headquarters in Lexington.

“It started in Lexington because that's where I live,” he said. “There was no real forethought to it. As an early company and with what we were doing, we weren't getting the investors’ attention, so we had to survive on revenue. We've really grown. We have some investors, but not a ton, but it's just always worked here. This is a unique thing. There are certainly aerospace hubs in Houston and Los Angeles, but this has really worked for kind of the engineering in the headquarters here. Seattle wasn't the place to make airplanes in the beginning and Silicon Valley was full of orchards at one point.

Space Tango has doubled in size every year since 2017. It has moved into its current space, which is much larger than the previous, has about 30 employees and several interns.