SAN PEDRO, Calif. — If you’ve been waiting on a kitchen appliance or set of golf clubs from Asia, expect to wait a little bit longer.

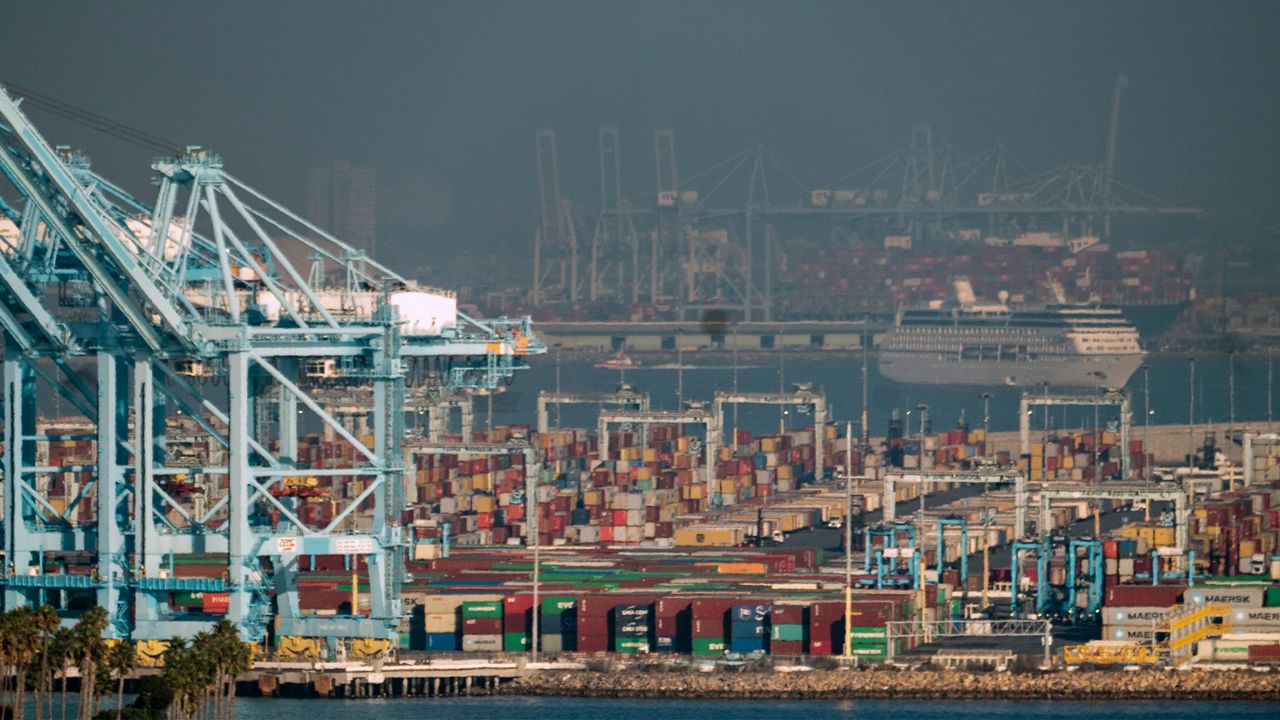

The Port of Los Angeles continues to be overwhelmed with imports.

“We’ve never seen volume like this in the first half of a calendar year,” said Port of LA Director Gene Seroka.

Port activity was 113% higher in March of this year compared with a year earlier, making it the busiest March in the port’s 114-year history and third busiest month ever.

“I would describe this as the port’s version of March Madness," Seroka added.

Driven by pandemic-induced, internet-fueled consumer spending, the port processed more than 957,000 container units last month — enough to stretch from Los Angeles to New York and halfway back across the country, he said.

And the surge is expected to continue. The National Retail Federation forecasts that 2021 retail sales will grow between 6.5 and 8.2% compared with 2020, keeping the port’s import traffic “strong well into the summertime,” as Seroka explained.

The port expects a 28% volume increase in April, a 45% increase in May and a milestone no Western Hemisphere port has ever before achieved by the end of June: 10,000 million container units for the fiscal year.

The port has been struggling to keep up with demand since February, when it was unable to accommodate all the arriving ships. Seroka said vessels will be forced to anchor before unloading through at least the end of May, but the situation is improving.

About 70% of the container ships arriving at the port in March were immediately anchored offshore while waiting to dock and unload. That’s an improvement over February, when 90% of ships were sent to anchor. The length of time they’re waiting on the water, however, is roughly the same at 7.9 days.

Once they’re berthed at the port, containers are now spending 3.8 days at the terminal before being shipped out, compared with an average of five days in February.

For containers that hit the road, they spend another 6.8 days waiting for warehouse space, also an improvement from February when it took 7.6 days. But when it comes to rail, containers are waiting almost 11 days to get where they need to go.

“The rapid succession of vessel calls, inclement weather across the country and one-way trade surge make it difficult to get rail cars, engine power and crews back to LA fast enough,” Seroka said. “We’re working closely with our partners to help improve this situation around the clock.”

One of issue driving the congestion is the balance of imports to exports, which are now 4 to 1. Exports from the port have dropped 26 out of the past 29 months.

“The ratio of loaded imports to exports in March is the highest gap we’ve seen in recent times,” said Seroka, adding that the port had to reposition 344,000 empty container units in March — three times as many as it did a year ago and the most it has ever repositioned in a single month.

There is also the issue of warehouse space to put all the incoming goods. The two billion square feet of warehousing in the area is “overflowing with cargo,” as Seroka explained.

“Underpinned with COVID-19 and the ability of our workforce to be on the job but at physically distanced locations also impacts how much cargo can move through,” he said. “There are more containers sitting at the port because there’s only so much room to put these shipments.”