WRIGHTSTOWN, Wis. — Over the past two years, Edgar Dinehart helped design and build an automated marble sorting machine for Wrightstown Middle School.

The project included skills such as conceptualizing, prototyping, trouble shooting and system programming.

“Doing math or something, you’re just adding, but this is something hands-on. We can put it together. We can see what we want to do,” Dinehart said. “When you actually put it on the wall, and you’re actually seeing the balls launch, it’s, like, ‘I did that. I learned how that works and I know the actual inner workings.'”

Dinehart is one of about 50 students at Wrightstown High School who worked on the project and came up with everything from its design to construction.

“This year I was helping install things on ladders and actually putting together the pneumatic systems and things like that,” he said.

Their creation will remain inside a classroom at Wrightstown Middle School.

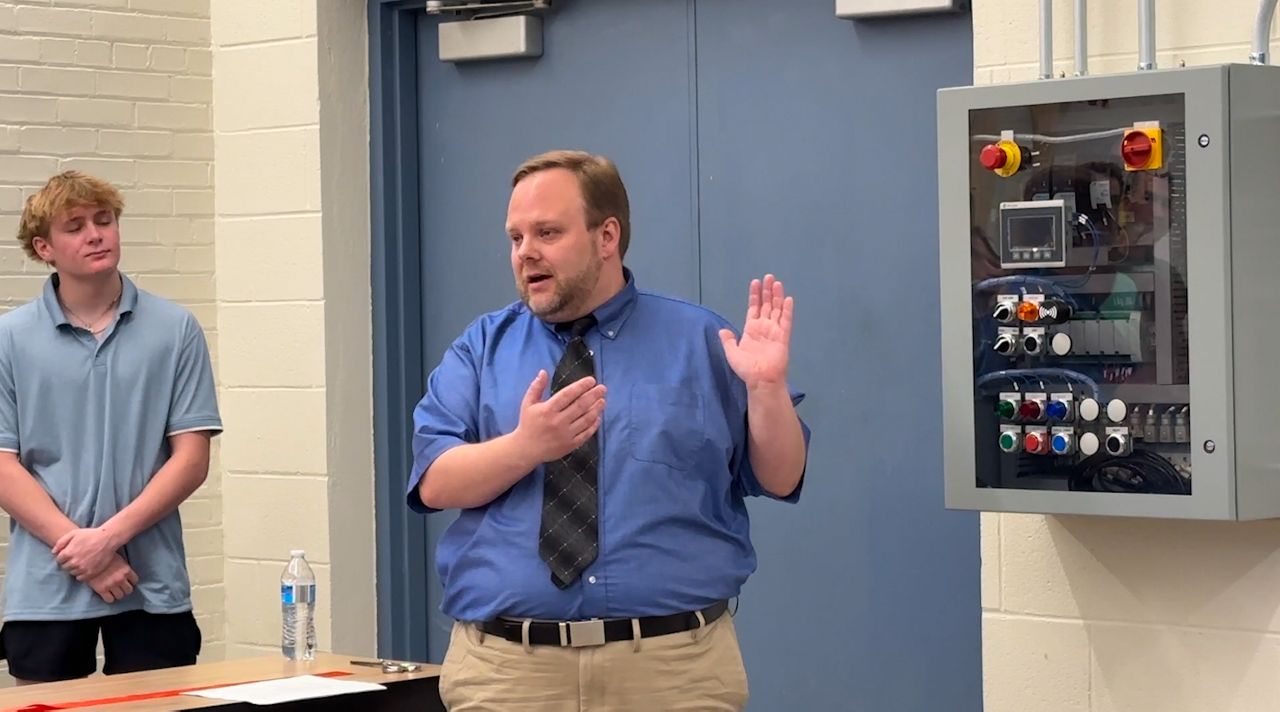

Scott Hanneman, who teaches technology and engineering at the high school, said he hopes seeing the automated marble sorting machine every day gets younger kids interested in robotics.

“The goal of this program is to allow students to interact with industrial automation,” Hanneman said. “It allows them to have hands-on experiences using tools and materials that they wouldn’t have normally had otherwise, while connecting it to real careers that have opportunities in northeast Wisconsin.”

Components were donated by Rockwell Automation/Allen Bradley via Werner Electric in Appleton, Wis. Precision Paper Converters and Suburban Enterprises also supported the project.

“The business involvement allowed us to get the materials for this project,” Hanneman said. “This project is above and beyond normal course work, but was key in providing those hands-on opportunities to allow our students to really make those decision about what real-life career they’d like to enter.”

Dinehart graduates from Wrightstown High School this spring, and said he’s decided to attend the University Wisconsin-La Crosse. He said he’s more confident in pursuing a career after working on this project.

“In the future, I want to do computer sciences, particularly programming PLCs and microcontrollers. This is really hands-on with how those will work,” he said. “Actually having the physical movement can help me understand what I need to program. I also learned a lot about the programming of this system itself.”