GREEN BAY, Wis. — For the last decade Chad Wertepny has helped build equipment used in cheese plants around the globe.

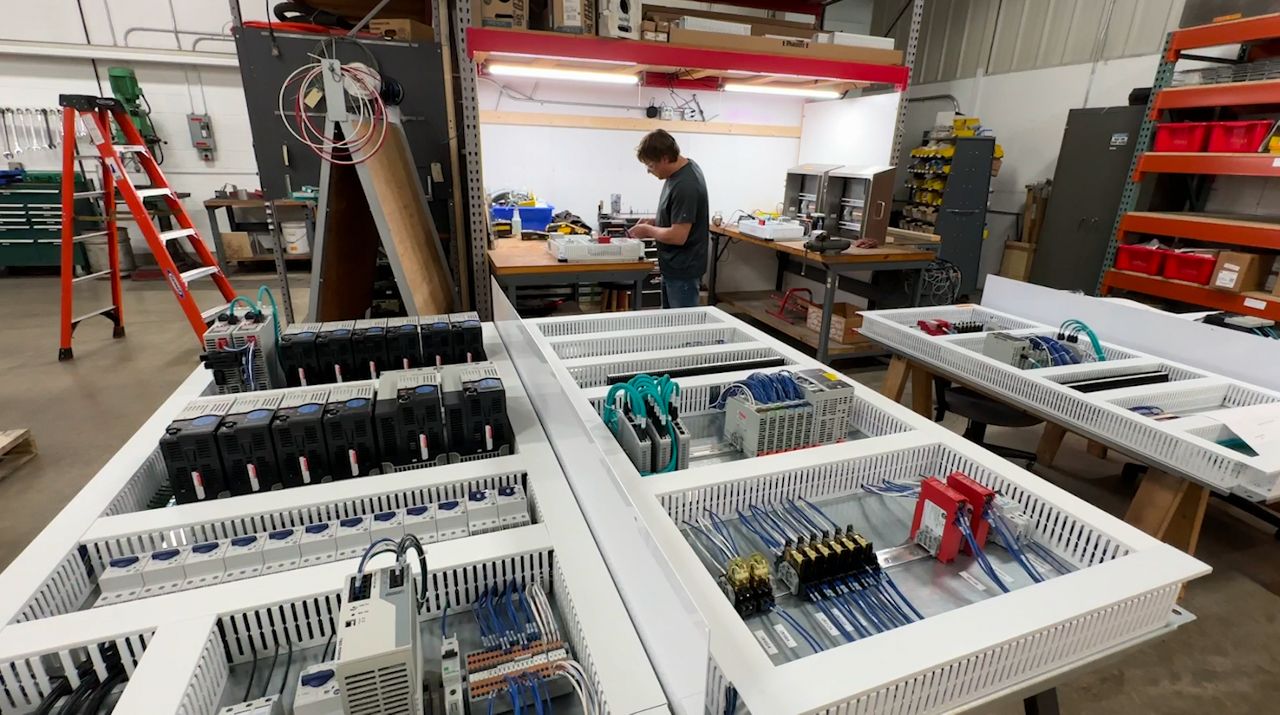

Wire by wire, he worked to finish up one of the panels for the machines built by Hart Design & Manufacturing in Green Bay.

“We’re building the back panels for some upcoming machines,” he said. “These are two smaller panels I’m working on, but as you can see, we have bigger main panels. We do everything from the main power coming in at 480 volts all the way down to the 24-volt DC controls.”

A family-owned business, the machines produced by Hart Design cuts natural cheese and packages processed cheeses. The business is busy with work booked into next year.

“I like the variety of the different machines. We do some filling lines, some casting lines, wrappers, and they’re all a little different, so it’s not always the same,” Wertepny said. “We’re still doing the wiring of the panels, but they’re all a little bit different.”

Hart is seeking people for open positions in electro-mechanical assembly and field service technicians.

Randy VerHaagh started with the company 15 years ago in field service. He’s now the assembly manager.

“Our (production) floor is going to be completely full this year. It’s a really good thing to have,” VerHaagh said. “We’re actually adding on in an area we’ve never built equipment before.”

VerHaagh said employee flexibility is part of the job when working in a specialized industry. Hart will provide training.

“A lot of our stuff is very similar, but very different. You just have to have a well-rounded mind,” he said. “We don’t produce anything on an assembly line, so everything is kind of based on memory. We might go two or three years before we build a casting line. You might build one your first day in the office and not build one for another three or four years.”

Wertepny gets to see the finished products in the field at installation.

“I take pride in what I do. I want to make sure everything is neat and nice and looks good,” he said. “From the customers, we’ve had some good feedback on how nice the panels look and the enclosures look. That makes you feel good.”

Careers at Hart Design & Manufacturing can be found, here.