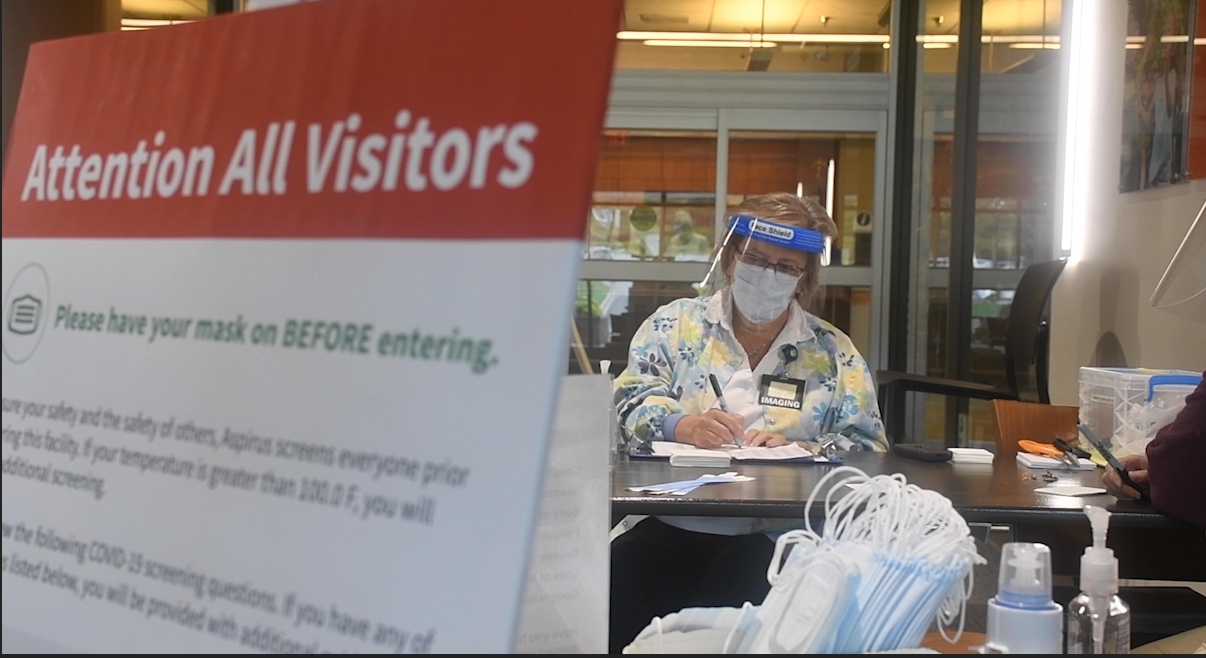

WAUSAU, Wis. (SPECTRUM NEWS) — Six months into the pandemic, personal protective equipment continues to be a sought after commodity.

Aspirus in Wausau says it’s “well positioned” on stocks of items ranging from masks to gloves.

“From N95s to isolation gowns to exam gloves to other face masks, we have invested in large quantities of those personal protective equipment so we can make sure our healthcare workers can perform their duties safely and be confident they can be safe as they move through this pandemic,” said Gary Rakes, vice president and chief supply chain officer with the healthcare provider.

The American Medical Association recently published a call for the federal coordination of production, distribution, and supply chain management of the gear by using the Defense Production Act. It specifically citied a persistent shortage of N95 masks.

The hardest hit, the organization says, are are physicians reopening practices to treat patients who have put off care for chronic conditions.

Many companies across the state have pivoted parts of their business to address some of the PPE needs brought on by the pandemic.

Alliance Laundry Systems in Ripon started work earlier this year in conjunction with the Stanford N95 Decontamination task force to develop processes and equipment modifications to decontaminate N95 masks three times.

Work is centered on the use of a 75-pound UniMac dryer.

“It’s a pretty unique drying process and airflow that allows it to maintain not just the temperature needed to decontaminate but the temperature consistently. You need those two factors,” said Randy Radtke, Alliance’s content and media relations manager. “We were able to, through some control programming and other things, make it work and maintain that temperature for the period necessary to decontaminate.”

Alliance got involved with the project to help the nation deal with the PPE shortage it was facing in the spring. The concept has been submitted to the Food and Drug Administration for potential approval.

“First and foremost, it was an opportunity to be part of coming up with a solution,” he said. “At that time the N95 mask was quite scarce and we wanted to do all we could to be a leader in coming up with a solution.”

Rakes said here is some concern looking forward at the upcoming flu season.

“That’s why we’ve invested more heavily in inventory so we can position ourselves better for a second or third surge if, or when, it happens later in the year,” he said. “I do feel much more comfortable today than I did four months ago.”