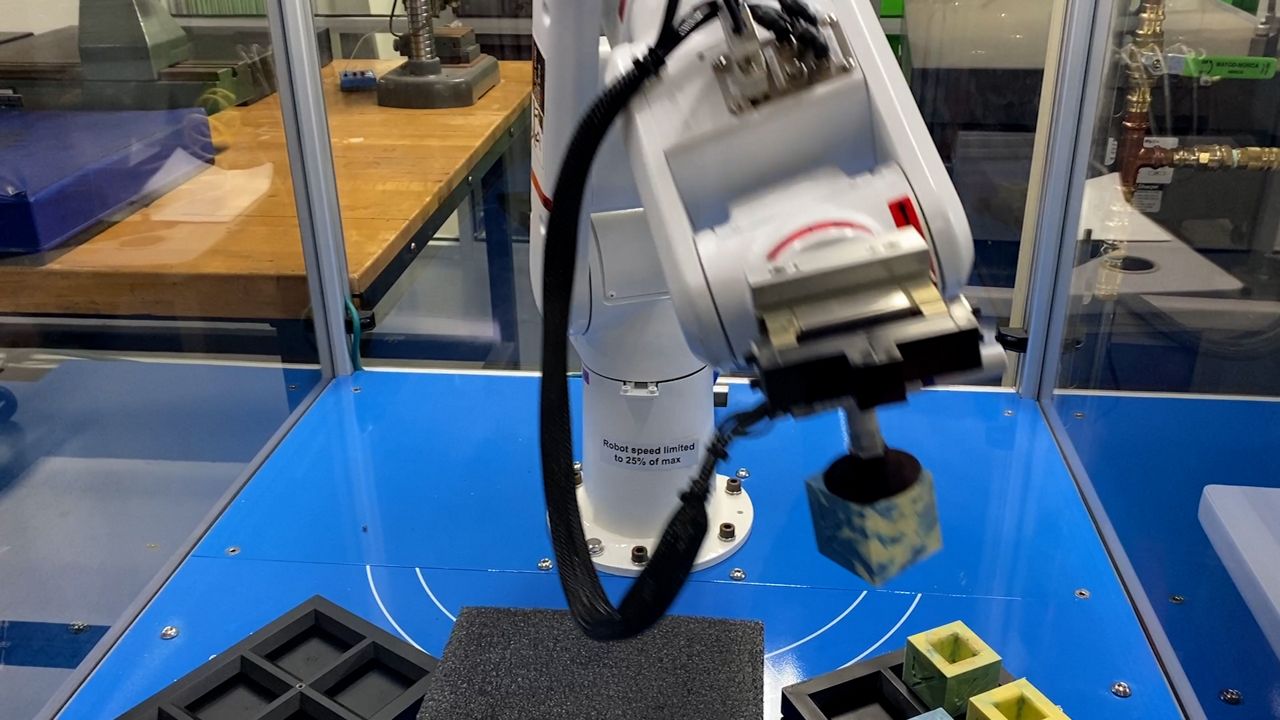

SPRINGFIELD, Ohio — Six years after students watched a robotic arm pick and place a small cube as a sign the future had arrived at Clark State College, the U.S. Labor Department is investing millions of dollars to bring Clark State’s robotic systems to the next level in the hopes students will pay it forward in Ohio’s workforce.

What You Need To Know

- Clark State College is one of 19 programs awarded millions of dollars for workforce development

- The university will use $3.5 million to build a smart factory

- The factory will create an integrated system of robots

- Students will train to understand and troubleshoot the system like a modern factory

Engineering students have been learning to master the kinds of technology they’d find in their next jobs, at factories across the Greater Dayton Area.

Nora Hatem is the industrial engineering coordinator at Clark State snd she said adding robotics to the school’s curriculum has helped students rise to meet the needs of a modern workforce.

“We use them to teach programing as well as application of robotics,” she said. “Within that first 15-week semester they’re already taking two robotics courses.”

The equipment came in 2015 thanks to a previous workforce development grant from the Labor Department.

Hatem said Clark State worked with local manufacturers to make sure the new additions represented the kinds of work students would encounter after graduation. Increasingly, that’s been robots.

“Some people feel that they’re replacing the people in the factories, but actually, you’re building up more technical skills to be able to run the robots,” she said.

The current engineering lab has multiple robots with different objectives like the pick and place robots and the Computer Numerical Control or CNC machines.

“We have to actually teach students how to write the code first, so they understand what they’re looking at on the machine,” Hatem said.

From there, the machine handles what the assembly workers once did, positioning and moving products for things like drilling, cutting, and welding.

“Then they’re hitting 'Go' and running that part,” Hatem said.

It’s a faster, safer, and more efficient model that gets even more efficient when everything is connected together. Hatem said that’s how the next labor grant will come into play.

“You’re not going to have a robot doing one thing,” she said. "You’re not going to have a CNC machine doing one thing. It’s all interconnected. So that’s what that smart factory is going to do.”

To boost the nation’s economy after a difficult year, the Labor Department awarded 19 grants to workforce development projects across the country. Clark State’s smart factory project received $3.5 million.

Hatem said that will fund the creation of an interconnected system of machines so students can learn how those machines will interact and how to respond to any issues or delays in the system.

“It’s teaching that basics of how do I control and program and what the next step will do with our new grant is to be able to take a singular robot doing pick and place and integrate it into a system that does something,” she said.

Hatem said it’s all about making the transition from Clark State to the an area manufacturer as easy as possible for the students and their future employers.

The Bureau of Labor Statistics reported the state ended 2020 at 5.5% unemployment. It’s a far cry from the 17.6% Ohio saw in April, but it’s still a point above pre-pandemic numbers.

Hatem hopes proper training for a hungry job force can help drive that number down.

Clark State students range from teens in high school, looking for a different kind of education, to recent graduates not seeking a traditional college track, to adults well into their careers hoping to develop a new skillset, either out of necessity or simply because they need a change.

The university plans to build up its smart factory over the next several months. It will be available for any students in the engineering program whether they’re seeking one-year certifications or four-year degrees.